Nov 11th 2020

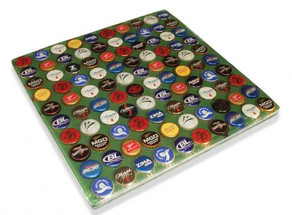

Bottle Cap Bar / Table Top

A multi‐layer project using Envirotex Lite pour on coating!

Project Instructions:

Bottle caps must be clean and dry; plan on 100 caps per square foot.

- If project base is made of wood, seal wood with a thin layer of white glue or paint the surface and let dry. The thin layer will seal the air pockets of the wood and prevent air from releasing bubbles in the thick layers of Envirotex Lite. If you choose to use Envirotex Lite as the thin sealing layer, apply with a sponge brush. Don't use the propane torch on this thin layer of Envirotex Lite. DO use the propane torch on subsequent layers.

- Projects with a permanent rim that contains the coating are most easy. Temporary borders may be created by affixing painters masking tape to sides of project, allowing tape to stick up and create a dam. Pour a layer of Envirotex Lite. Remove tape 8‐10 hours later and apply new tape for each layer. The tape will NOT result in a straight, smooth edge. For the final layer, we recommend sanding the sharp edge with sandpaper and pouring Envirotex Lite on the top and allowing coating to flow over the side of the project; this layer will conceal all sanding marks and will make the sides of the project clear and smooth. Drips may be sanded from the underside later. Slats of wood coated with two layers of paste wax can also be used for temporary border; seams of the wood slats must be taped to prevent coating from flowing and dripping through seams.

- Glue bottle caps in place with white glue that dries clear; fill ruffled area of bottle cap with glue to prevent air from escaping from underneath. Allow glue to dry overnight. Caps must be glued in place because cap can lift and float.

- Apply the first of several layers of Envirotex Lite; use 6 ounces of pour on coating for every 12 square inches. Most bottle cap projects will require 3‐5 layers of 6 ounce volume; allow 8 hours curing time between layers. Bubbles will form around the sides of the cap, swish a brush around the cap to encourage the bubbles to release and rise.

- Coating may be sanded between layers but it's not necessary. If surface is sanded, wipe with alcohol or acetone and a clean rag to remove dust particles. If surface is sanded it must be re‐coated.

TIPS on BLENDING COATING: always measure equal parts of resin and hardener. Blend in bucket with (only) a wood paint stick for two minutes, mixing vigorously while scraping sides and bottom of bucket. Then pour coating into a new, clean bucket and blend for another minute. Thorough blending is achieved by the above mixing method only! Discard mixing stick. Pour coating onto project immediately. Use propane torch to remove bubbles from coating. You may need to use propane torch several times during a forty five minute period following application. Important: read all instructions included in kit.